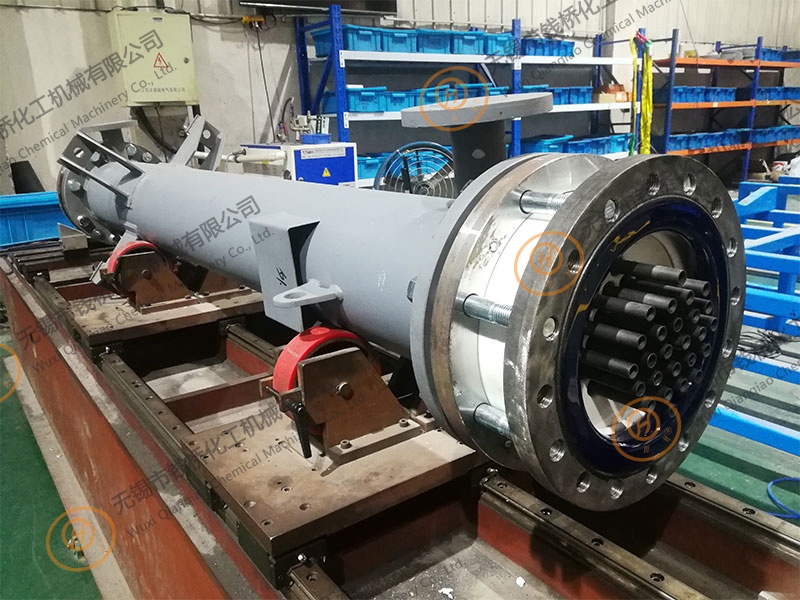

SIC tube heat exchanger

SIC tube heat exchanger, consisting of corrosion-resistant tube sheets and silicon carbide tubes, is the best solution for the most demanding corrosive conditions.

SIC tubular heat exchangers use heat-resistant tubes made of corrosion-resistant silicon carbide that are ideal for heating, cooling and condensing chemically corrosive process media. Typical applications include: bromine, sulfuric acid, hydrofluoric acid, nitric acid, hydrochloric acid and other acids; bases; halogenated compounds; salt solutions and organic compounds.

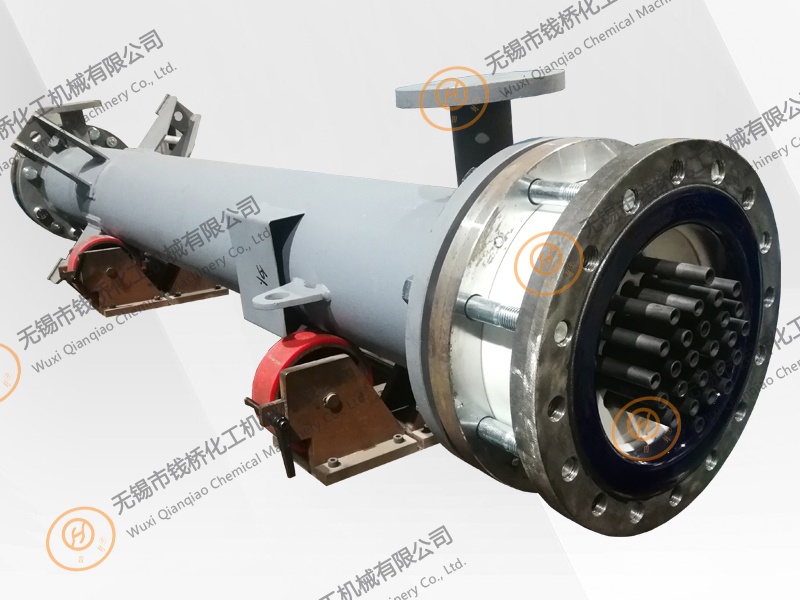

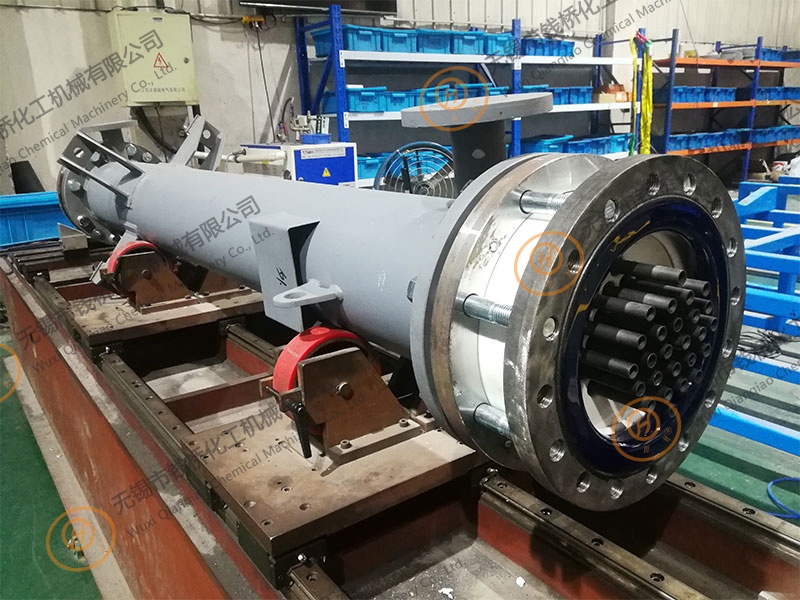

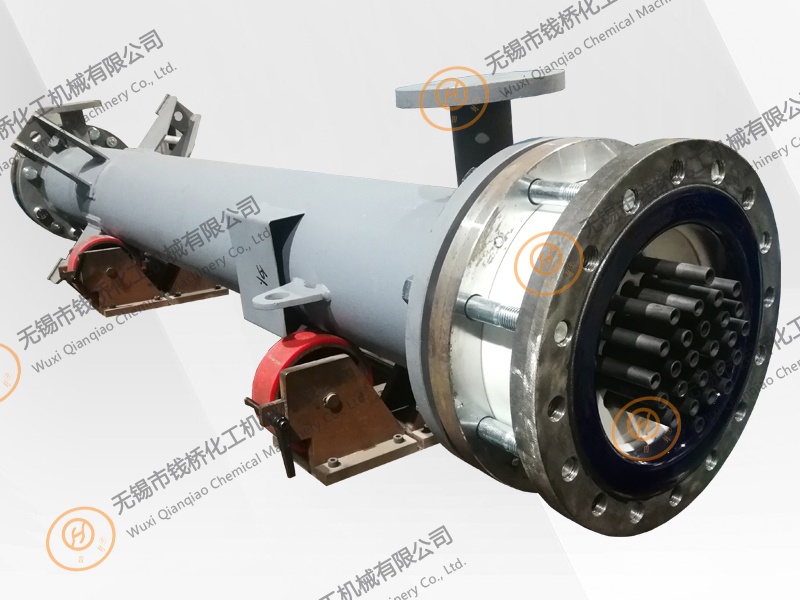

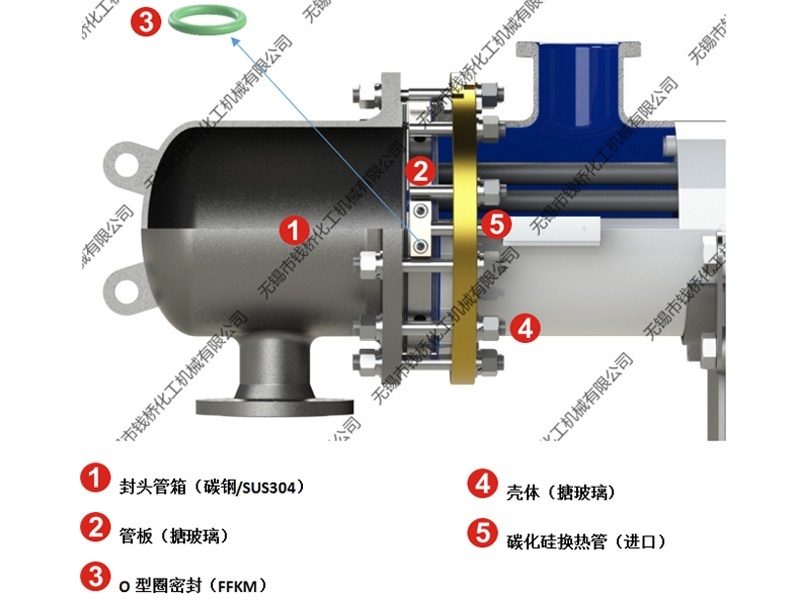

Imported SIC heat exchange

● Test each heat exchange tube under pressure of 185 Bar before installation

● Heat exchanger housing diameter range from DN100 to DN600

● The standard length of the heat exchange tube is 1000 to 4000mm

● Heat exchange area is 0.32 to 58 square

● Heat exchange tube diameter is 26mm

● Horizontal or vertical installation

● Applicable temperature range -19℃ to 250℃

● Applicable pressure range -0.1Mpa to 0.6Mpa

● Comply with CE, ATEX, FDA

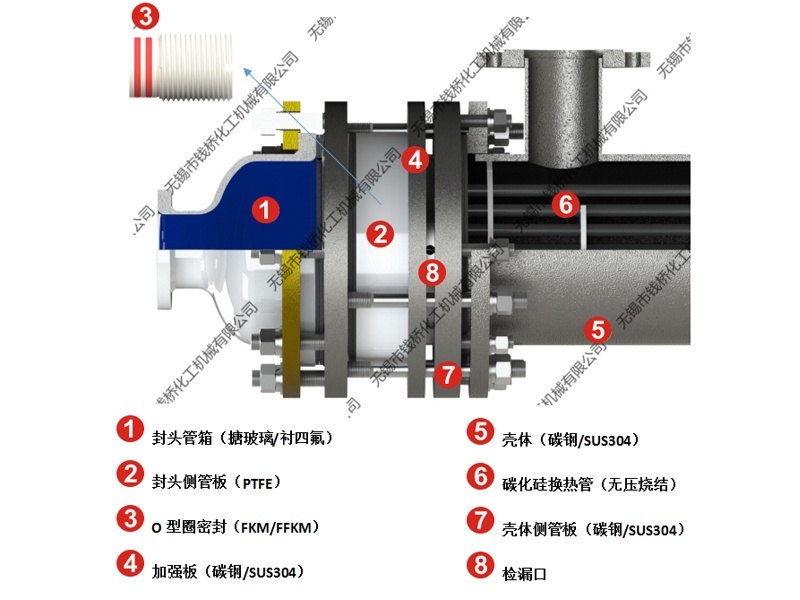

● Test each heat exchange tube under pressure of 185 Bar before installation

● Heat exchanger housing diameter range from DN100 to DN1000

● The standard length of the heat exchange tube is 1000 to 4000mm

● Heat exchange area is 1 to 200 square

● Heat exchange tube diameter is 14mm and 19mm

● Horizontal or vertical installation

● Applicable temperature range -19℃ to 230℃

● Applicable pressure range -0.1Mpa to 1.0Mpa

● Comply with CE, ATEX, FDA

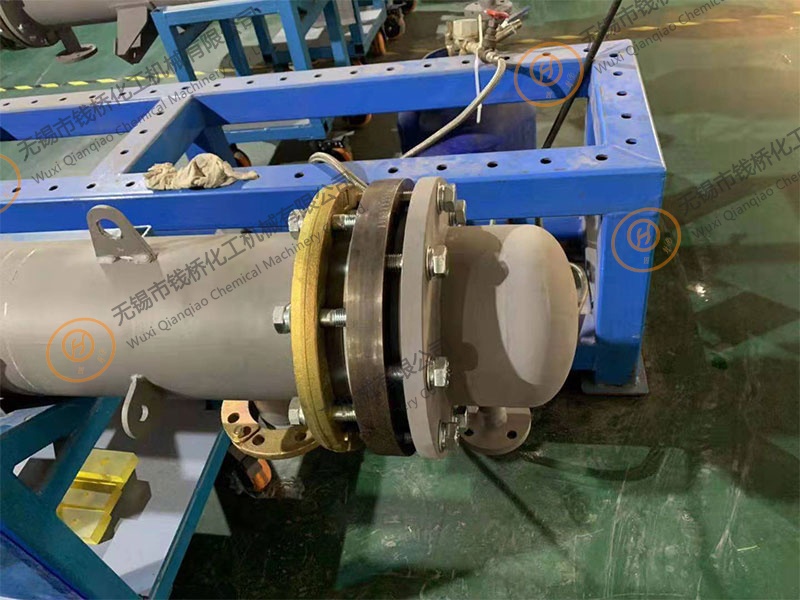

● Combined with the internal test data and the application of a number of practical cases, it is proved that this type is the most reliable, most stable, the best temperature resistance, the best pressure bearing and the most widely applicable structure in the existing structure of silicon carbide tube heat exchanger.

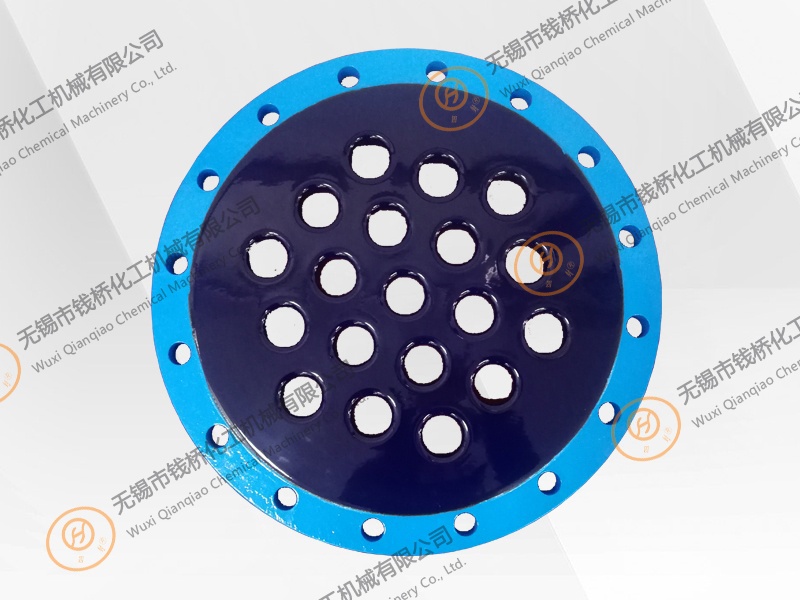

![Super type [steel lined PTFE] SIC heat exchange Super type [steel lined PTFE] SIC heat exchange](/uploads/2020/01/181641392547.jpg)

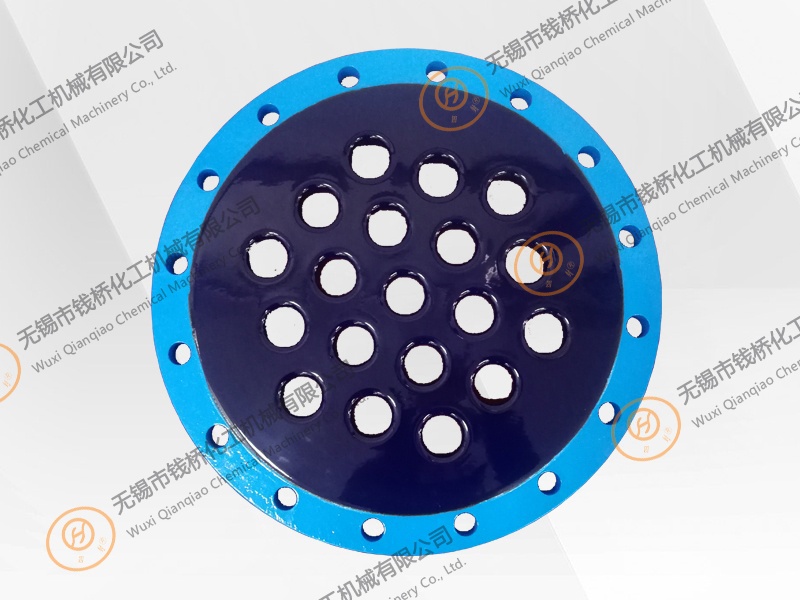

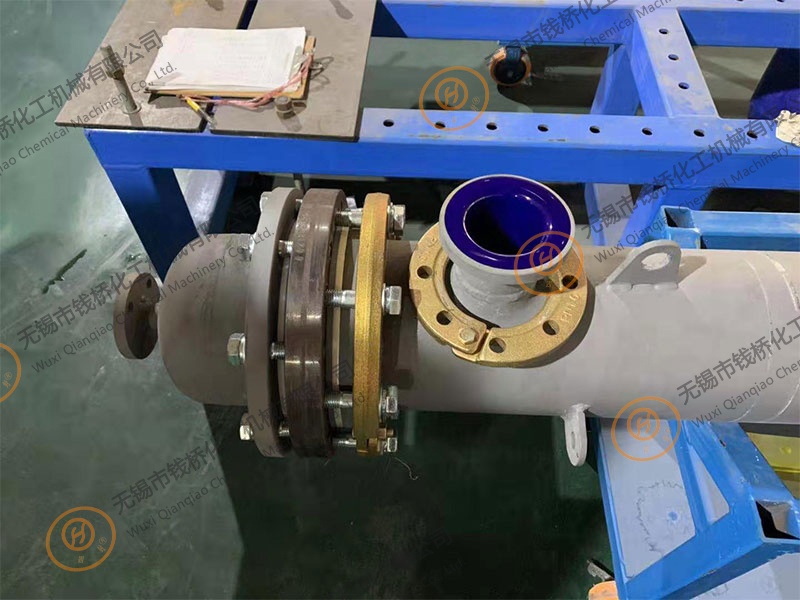

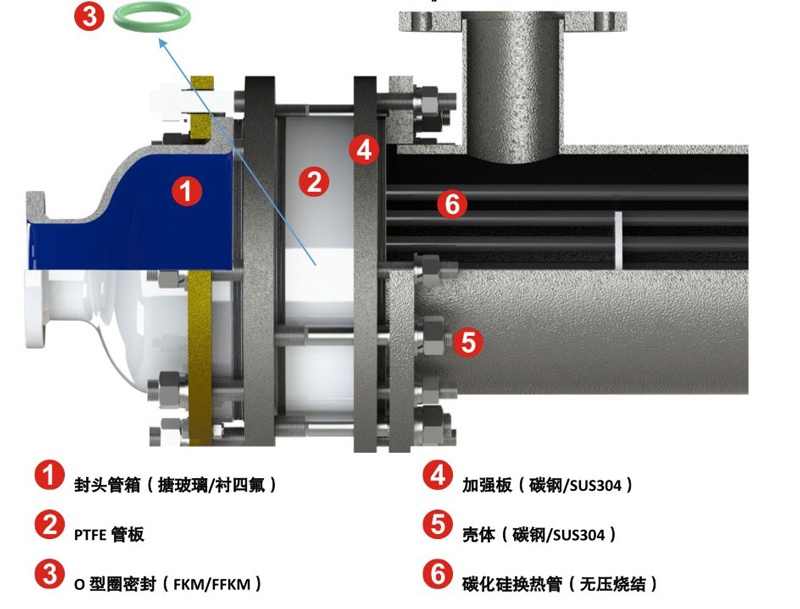

Reinforced double tube plate [steel lined F4 or steel lined PFA] SIC heat exchange

● Test each heat exchange tube under pressure of 185 Bar before installation

● Heat exchanger housing diameter range from DN100 to DN600

● The standard length of the heat exchange tube is 1000 to 3000mm

● Heat exchange area is 1 to 40 square

● Heat exchange tube diameter is 14mm and 19mm

● Horizontal or vertical installation

● steel lining F4 Applicable temperature range -19℃ to 120℃

● steel lining PFA Applicable temperature range -19℃ to 120℃

● Applicable pressure range -0.1Mpa to 0.6Mpa

● Comply with CE, ATEX, FDA

● Double tubeSheet deSign

It is possible to separate the process fluid and the service fluid with a separation chamber, so that in case of o-ring leaking no mix will occur between the two fluids.

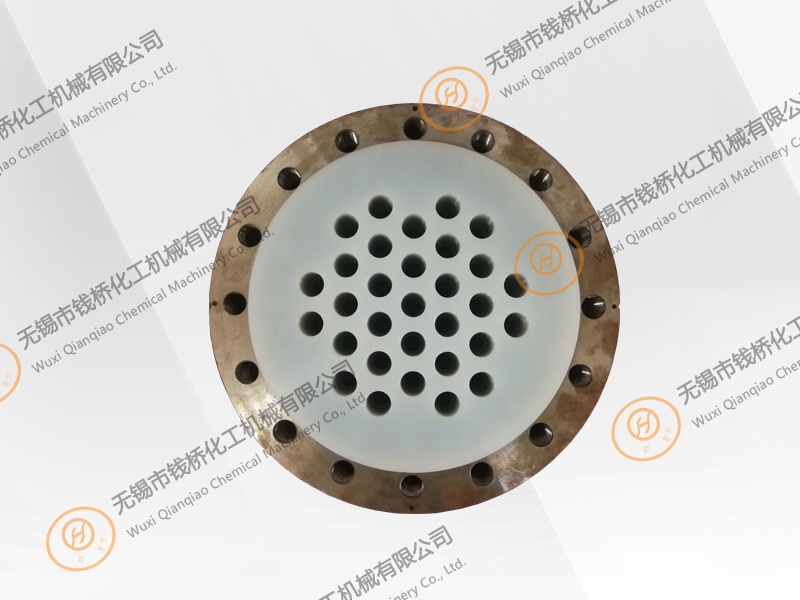

![Reinforced double tube plate [steel lined F4 or steel lined PFA] SIC heat exchange Reinforced double tube plate [steel lined F4 or steel lined PFA] SIC heat exchange](/uploads/2020/01/181644209176.jpg)

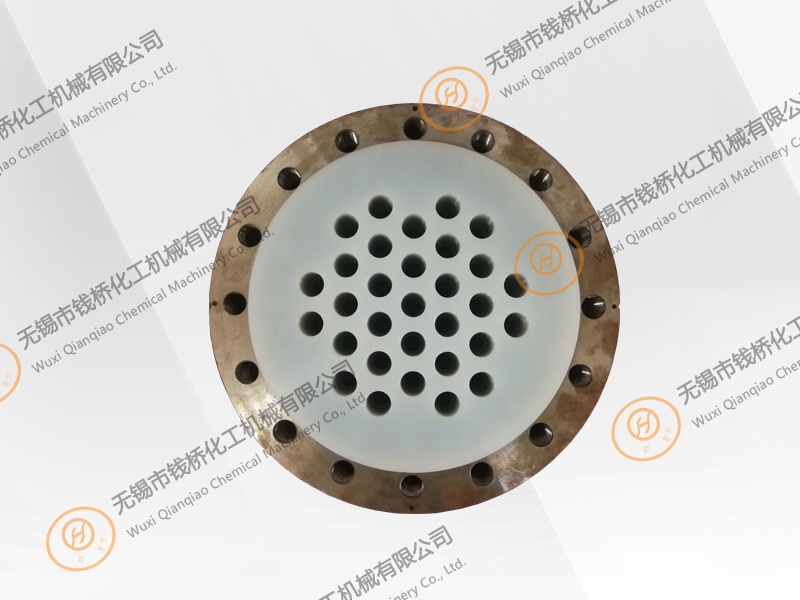

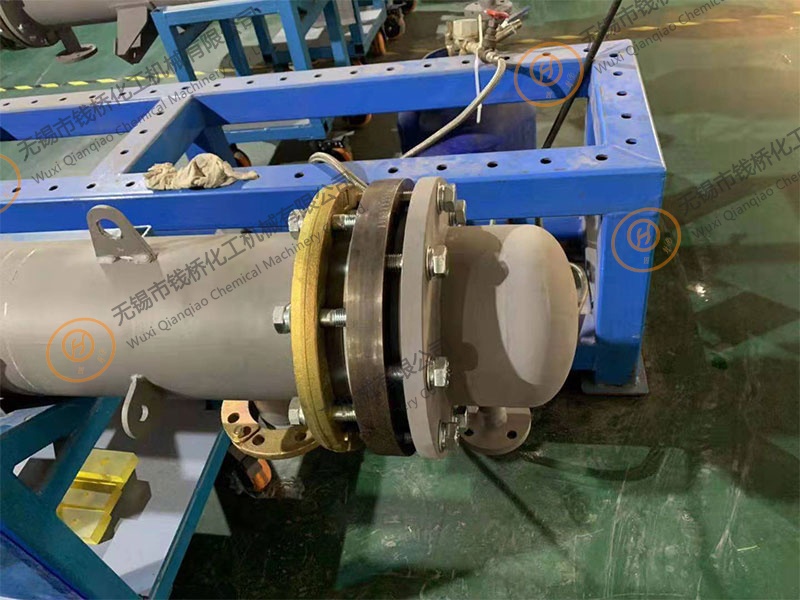

● Test each heat exchange tube under pressure of 185 Bar before installation

● Heat exchanger housing diameter range from DN100 to DN600

● The standard length of the heat exchange tube is 1000 to 3000mm

● Heat exchange area is 1 to 40 square

● Heat exchange tube diameter is 14mm and 19mm

● Horizontal or vertical installation

● steel lining F4 Applicable temperature range -19℃ to 120℃

● steel lining PFA Applicable temperature range -19℃ to 120℃

● Applicable pressure range -0.1Mpa to 0.6Mpa

● Comply with CE, ATEX, FDA

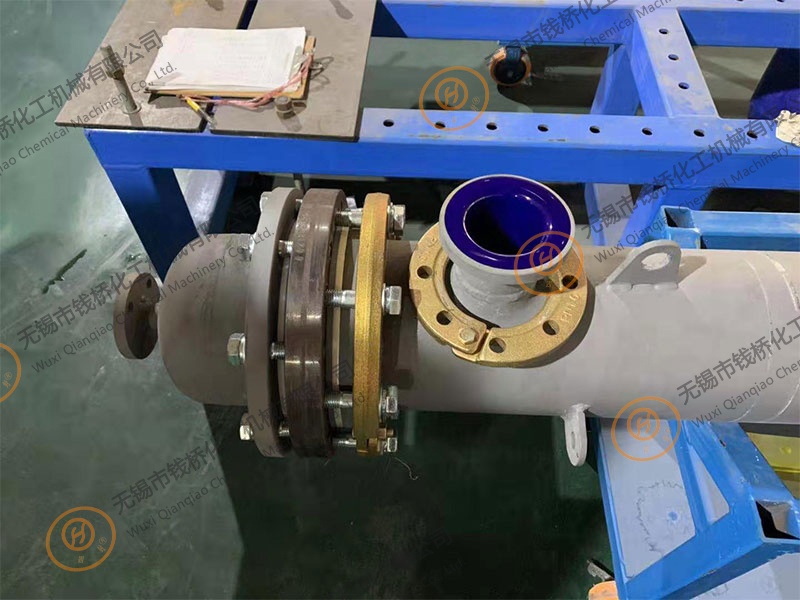

![Reinforced type [steel lined F4 or steel lined PFA] SIC heat exchange Reinforced type [steel lined F4 or steel lined PFA] SIC heat exchange](/uploads/2020/01/181645494495.jpg)

● Test each heat exchange tube under pressure of 185 Bar before installation

● Heat exchanger housing diameter range from DN100 to DN600

● The standard length of the heat exchange tube is 1000 to 3000mm

● Heat exchange area is 1 to 60 square

● Heat exchange tube diameter is 14mm and 19mm

● Horizontal or vertical installation

● Applicable temperature range -19℃ to 100℃

● Applicable pressure range -0.1Mpa to 0.6Mpa

● Comply with CE, ATEX, FDA

● Double tubeSheet deSign

It is possible to separate the process fluid and the service fluid with a separation chamber, so that in case of o-ring leaking no mix will occur between the two fluids.

● Test each heat exchange tube under pressure of 185 Bar before installation

● Heat exchanger housing diameter range from DN100 to DN600

● The standard length of the heat exchange tube is 1000 to 3000mm

● Heat exchange area is 1 to 60 square

● Heat exchange tube diameter is 14mm and 19mm

● Horizontal or vertical installation

● Applicable temperature range -19℃ to 100℃

● Applicable pressure range -0.1Mpa to 0.3Mpa

● Comply with CE, ATEX, FDA

Red column must be filled Click to download

|

Design requests of SIC |

|||||

|

Device number |

|

|

|||

|

|

|

Jacket |

in side of heat exchanger |

||

|

Fluid name / component |

|

|

|

||

|

Total flow |

kg/h |

|

|

||

|

Gas flow |

kg/h |

|

|

||

|

Liquid flow |

kg/h |

|

|

||

|

Non condensable material flow |

kg/h |

|

|

||

|

Tempreture ( In / Out) |

°C |

|

|

|

|

|

Freezing point / Boiling point |

°C |

|

|

||

|

Density |

kg/m3 |

|

|

||

|

Viscosity |

cP |

|

|

||

|

Gas molecular weigh |

g/mol |

|

|

||

|

Molecular weight of non condensates |

g/mol |

|

|

||

|

Specific heat |

cal/g/k |

|

|

||

|

Thermal conductivity |

kcal/m/K/h |

|

|

||

|

latent heat |

kcal/kg |

|

|

||

|

Inlet pressure (absolute pressure) |

Mpa |

|

|

|

|

|

Current Speed |

m/s |

|

|

||

|

Pressure drop |

bar |

|

|

||

|

Fouling coefficient |

kcal/h/m2/°C |

|

|

||

|

Heat exchange capacity |

kcal/h |

|

|||

|

Heat transfer coefficient(clean / dirty / service side) |

kcal/h/m2/°C |

|

|||

|

Corrected logarithmic mean temperature difference |

°C |

|

|||

|

Heat exchange area (required / provided) |

m2 |

|

|||

|

Equipment selection data |

|||||

|

Design temperature |

°C |

|

|

||

|

Design pressure |

barg |

|

|

||

|

Test pressure |

barg |

|

|

||

|

Process number |

|

|

|

||

|

Inlet pipe diameter |

mm |

|

|

||

|

Outlet pipe diameter |

mm |

|

|

||

|

Material |

|

|

|

||

|

Weight (empty / full water) |

kg |

|

|||

|

Installation method |

|

|

|||

|

碳化硅腐蝕性能表 |

||||

|

測(cè)試環(huán)境 Test Environment |

腐蝕量 |

(mg/cm2yr) |

||

|

(Wt%) |

溫度 Temp |

無(wú)壓燒結(jié)碳化硅** |

反應(yīng)燒結(jié)碳化硅 |

|

|

98% H2SO4 |

100 |

1.8 |

55 |

|

|

50% NaOH |

100 |

2.6 |

>1000 |

|

|

53% HF |

25 |

<0.2 |

7.9 |

|

|

85% H3PO4 |

100 |

<0.2 |

8.8 |

|

|

70% HNO3 |

100 |

<0.2 |

0.5 |

|

|

45% KOH |

100 |

<0.2 |

>1000 |

|

|

25% HCI |

70 |

<0.2 |

0.9 |

|

|

10% HF plus 57% HNO3 |

25 |

<0.2 |

>1000 |

|

|

無(wú)錫市錢橋化工機(jī)械有限公司所生產(chǎn)設(shè)備均使用無(wú)壓燒結(jié)碳化硅** |

||||

|

|

|

|

|

|

SIC tubular heat exchangers use heat-resistant tubes made of corrosion-resistant silicon carbide that are ideal for heating, cooling and condensing chemically corrosive process media. Typical applications include: bromine, sulfuric acid, hydrofluoric acid, nitric acid, hydrochloric acid and other acids; bases; halogenated compounds; salt solutions and organic compounds.